Four steel wire spiral Hydraulic Hose SAE100 R12 Super high Pressure

Four steel wire spiral hydraulic hose SAE 100R12

SAE 100 R12 hose, R12 hydraulic hose, R12 hose, R12 oil pressure hose, R12 hose, R12, oil transfer hose, high pressure hydraulic hose, high pressure hose, hose, hydraulic fluid hose.

Application: Transfer of hydraulic oil at very high pressures and peaks. Oil, construction, agriculture, industry and automotive industries

Construction:

Tube: Oil resistant synthetic rubber Reinforcement: Four high tensile steel wire spiral layers. Cover: Black, abrasion and weather resistant synthetic rubber, MSHA accepted. Temperature: -40℃ to +125 ℃

Fou steel wire spiral Hydraulic Hose SAE100R12

SAE R12/ SAE 100 R12 hydraulic hose is suitable for industrial, heavy use and high impulse.

It consists of a synthetic rubber inner tube, reinforced by four metal wires.

This four-layer reinforcement makes it a suitable hose for applications requiring high pressure. Its outer layer is made of gray synthetic rubber, which is resistant to adverse weather conditions, oils and abrasion.

It is available in nominal diameters (DN) from 3/8" to 1" 1/2. It can withstand working pressures from 276 bar to 172 bar.

The operating temperature is -40°C to +100°C. It can be used with standard connections and external stripping or with BW connections without stripping

The SAE 100 R12 hydraulic hose is suitable for hydraulic lines and industrial systems. Features: High resistance to oil, extreme pressure, abrasion, corrosion, weathering, ozone, cutting, aging and sunlight exposure.

Specification:

| Part No. | I.D. | O.D. | W.P | B.P | B.R | W.T | |||

| Dash | Inch | mm | mm | MPa | PSI | MPa | PSI | mm | kg/m |

| R12-06 | 3/8″ | 9.5 | 20.2 | 28.0 | 4060 | 112 | 16240 | 125 | 0.707 |

| R12-08 | 1/2″ | 12.7 | 23.5 | 28.0 | 4060 | 112 | 16240 | 180 | 0.871 |

| R12-10 | 5/8″ | 15.9 | 27.3 | 28.0 | 4060 | 112 | 16240 | 200 | 1.107 |

| R12-12 | 3/4″ | 19.1 | 31.0 | 28.0 | 4060 | 112 | 16240 | 240 | 1.339 |

| R12-16 | 1″ | 25.4 | 38.0 | 28.0 | 4060 | 112 | 16240 | 300 | 1.984 |

| R12-20 | 1.1/4″ | 31.8 | 47.0 | 21.0 | 3045 | 84 | 12180 | 420 | 2.532 |

| R12-24 | 1.1/2″ | 38.1 | 54.0 | 17.5 | 2540 | 70 | 10150 | 500 | 3.040 |

| R12-32 | 2″ | 50.8 | 67.5 | 17.5 | 2540 | 70 | 10150 | 640 | 4.586 |

SAE 100 R12 steel wire spiraled hydraulic hose

SAE 100 R12 steel wire spiraled hydraulic hose is suitable for delivering petroleum-based hydraulic oils and it is mainly used in high pressure working conditions. It is composed of three parts: tube, reinforcement and cover. The tube is made from black oil resistant synthetic rubber, making it have outstanding performance in delivering petroleum-based hydraulic oils. The reinforcement is made from four layers of high tensile and high strength thick spiraled steel wire in alternating direction, making the hose resistant to extremely high pressure. The cover is made from high quality synthetic rubber, which is resistant to abrasion, corrosion, weather, ozone, cut, aging and sunlight.SAE 100R12 Hydraulic Hose – 4 Spiral High Pressure Hydraulic Hose

High pressure hydraulic hose. Highly flexible hydraulic hose with 4 spiral steel wire re-enforcement. Ideal for when low bend radius is essential. High Pressure hydraulic hose Reinforcement: Four high tensile steel wire spirals Cover: Abrasion resistant, ozone and weather resistant synthetic rubber, MSHA approved Temperature range: -40F to +250F. High pressure power lines in heavy duty environmental conditions, specific installations with severe abrasion conditions, marine applications, underground and open pit miningRECOMMENDED FLUIDS

Mineral oils, vegetable oils and synthetic ester based oils (up to 212°F 100°C), glycols and polyglycols, mineral oils in aqueous emulsion, water

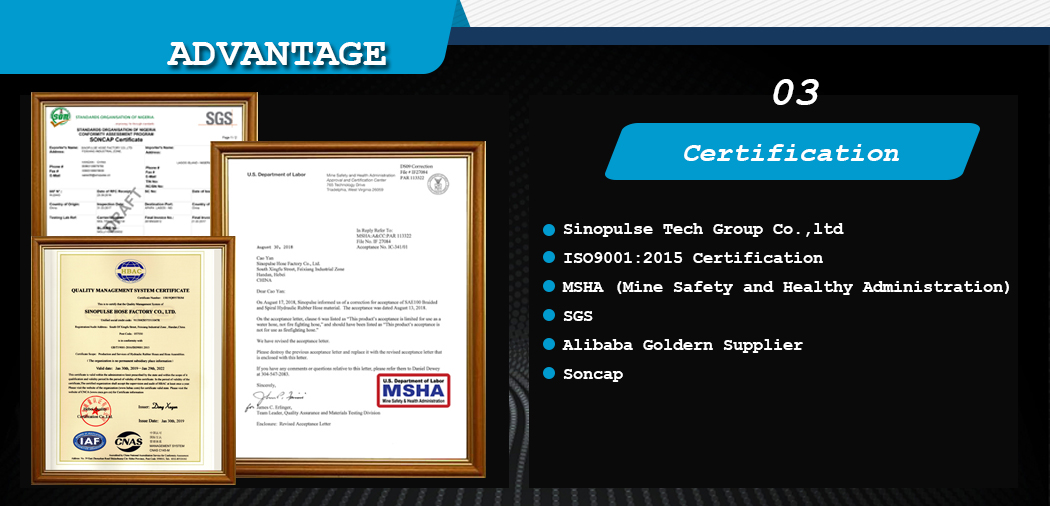

- Our company is the long term ISO9001: 2015 Certification manufacturer and exporter for full range Hydraulic hose, Industrial Hoses, PVC hose pipe, Pneumatic tubes.

- Our products passed the MSHA no. IC-341/01. We are the trust worthy manufacturer, which are professional and reliable supplier

- Our hoses passed the Gost certification this year, and we have done the cold weather testing of the hose up to -40℃.

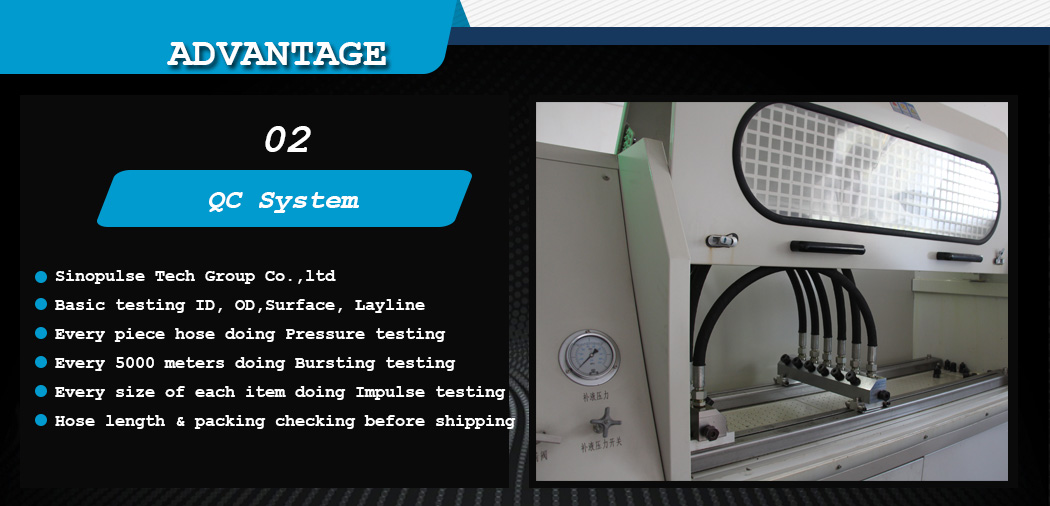

- The most important reason to choose us is what the test we are doing everyday of the products before, during and after production.

- For example, before the production, we have done various kinds of test for the rubber material , like the rubber strength, rubber hardness, rubber vulcanization, adhesive, aging, ozone, cold weather. And the testing for the steel wire strength.

- During the production, we have the Identity card to show the production progress, who will responsible for the each production chain.

- After the production, we need to testing the proof pressure 2 times than the working pressure every roll of hoses, and test the bursting pressure 4 times than the working pressure.

- We have done the impulse test to show the products working life, It should be noted that our products are fully compliant with SAE 100R12